Industrial I/O

Industrial I/O

Industrial I/O

Factories are expanding to enable Industry 4.0, buildings are getting smarter, and robotics are continually evolving. Such widespread innovation drives designers in various industries to optimize and enhance their products. Our industrial digital and analog input/output (I/O) IC portfolio provide the highest levels of robustness on the market with the highest integration and software configurability for a more flexible solution. High voltage industrial digital input (DI) and digital output (DO) signals (also called binary signals), typically range in magnitude from 0 V to 24 V. Digital I/O signals are used by industrial automation and control equipment, operating in harsh and noisy environments, to communicate on/off status between remote devices and controllers. Our industrial digital I/O ICs perform voltage level translation while providing circuit protection. Many also perform data serialization to allow economical operation through digital signal isolators. Analog I/O signals are used in both factory and build automation to enable smarter sensing and push intelligence at the edge. Our best-in-class analog input (AI), analog output (AO), and configurable analog input/output (CIO) ICs provide the highest levels of system accuracy in the market with per-channel software configurability. Factory calibration and robust integrated protection reduce overall system cost and size. Innovative designs decrease power consumption allowing operation of more channels without derating for ambient temperature. Key benefits: most robust solutions on the market with the highest integration; software configurability provides flexibility and reduces end product SKUs; and fast time to market with the best support in the industry.

Factories are expanding to enable Industry 4.0, buildings are getting smarter, and robotics are continually evolving. Such widespread innovation drives designers in various industries to optimize and enhance their products. Our industrial digital and analog input/output (I/O) IC portfolio provide the highest levels of robustness on the market with the highest integration and software configurability for a more flexible solution. High voltage industrial digital input (DI) and digital output (DO) signals (also called binary signals), typically range in magnitude from 0 V to 24 V. Digital I/O signals are used by industrial automation and control equipment, operating in harsh and noisy environments, to communicate on/off status between remote devices and controllers. Our industrial digital I/O ICs perform voltage level translation while providing circuit protection. Many also perform data serialization to allow economical operation through digital signal isolators. Analog I/O signals are used in both factory and build automation to enable smarter sensing and push intelligence at the edge. Our best-in-class analog input (AI), analog output (AO), and configurable analog input/output (CIO) ICs provide the highest levels of system accuracy in the market with per-channel software configurability. Factory calibration and robust integrated protection reduce overall system cost and size. Innovative designs decrease power consumption allowing operation of more channels without derating for ambient temperature. Key benefits: most robust solutions on the market with the highest integration; software configurability provides flexibility and reduces end product SKUs; and fast time to market with the best support in the industry.

Viewing:

Category Details

Products in Category

Featured Evaluation Boards

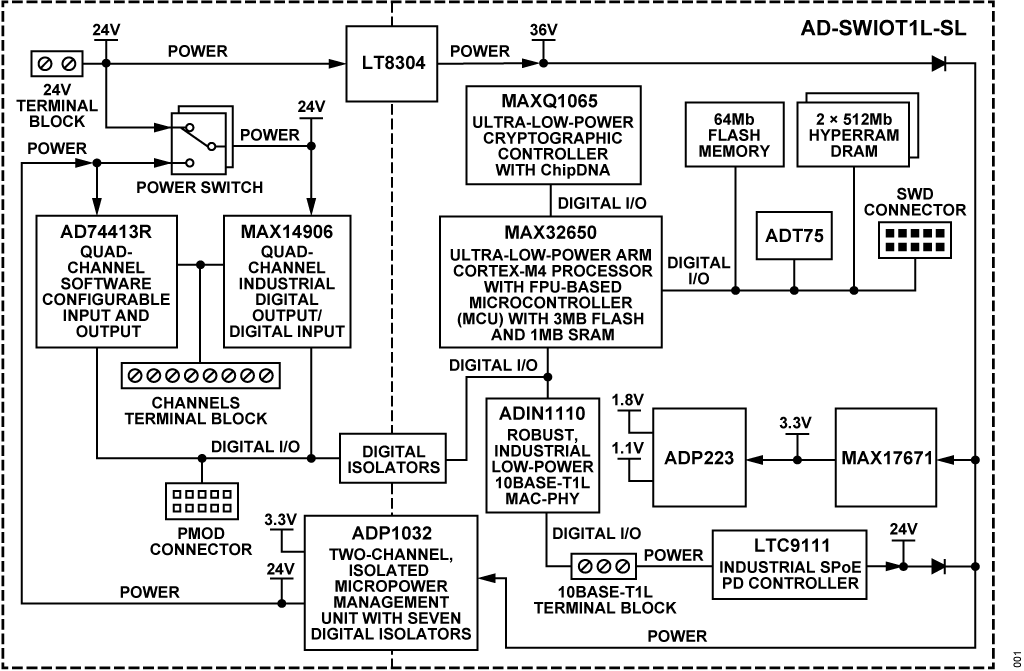

AD-SWIOT1L-SL

The AD-SWIOT1L-SL provides a complete software and hardware platform for prototyping intelligent, secure, network capable field devices.

The design incorporates the AD74413R Quad-Channel, Software Configurable Input and Output and the MAX14906 Quad-Channel Industrial Digital Output/Digital Input ICs, allowing the multiplexing of several analog and digital functions on four channels which can be independently configurable through software to act as:

- voltage output / input

- current output / input

- digital input / output

- RTD measurement

A 10 Mbps single-pair Ethernet link, using the ADIN1110 10BASE-T1L MAC/PHY, enables remote data acquisition and device configuration. The 10BASE-T1L interface can also be used for powering the system via the Single-pair Power over Ethernet (SPoE) technology using the LTC9111 Powered Device (PD) controller. This way, power and data for the system is provided over the same cable to significantly simplify the cabling infrastructure and cost.

For applications requiring high current capabilities, the system can be powered from an external 24 V supply and up to 1.2 A can be output on any of the channels configured as digital outputs. The power supply solution also includes the ADP1032 high performance, isolated micropower management unit (PMU) to provide power and digital control for software configurable I/O devices in one of the most compact formats. The LT8304 Micropower No-Opto Isolated Flyback Converter completes the power tree to provide isolated power to the digital part of the design.

The on-board MAX32650 Ultralow Power ARM® Cortex®-M4 Microcontroller exposes all the necessary debug and programming features to enable a complete software development experience with the system. It is coupled with a 1 Gb (128 MB) external RAM and a 64 Mb (8 MB) external flash memory to meet the most demanding applications and provide the flexibility to implement any protocol stack. Security features are enabled by the MAXQ1065 security coprocessor.

The system is accompanied by an open-source software stack and associated collateral, enabling a complete experience from evaluation and prototyping all the way to production firmware and applications development. An external programmer such as the MAX32625PICO MAXDAP Programming Adapter, or any other similar programmer supporting the SWD interface, is required to enable firmware programming and debug. The system’s firmware is based on Analog Devices’ open-source no-OS framework which includes all the tools required for embedded code development and debugging as well as libraries enabling host-side connectivity for system configuration and data transfer over the UART or the 10BASE-T1L interfaces. A PC application with a user-friendly graphical interface is provided to enable easy system configuration and displaying the acquired data in different ways.

| I/O | |

| Channels | 4 Software Configurable IO channels |

| Digital input | Type 1 and 3, or Type 2 |

| Digital output | High-Side (HS) Switch or Push-Pull (PP) Driver |

| Analog input | Voltage (0 V to 10 V), Current (0 mA to 25 mA) |

| Analog output | Voltage (0 V to 11 V), Current (0 mA to 25 mA) |

| RTD measurements | 2-wire RTD (0 Ω to 1 MΩ) |

| Computing Resources | |

| CPU | MAX32650 Ultra-Low-Power Arm Cortex-M4 with FPU-Based Microcontroller (MCU) with 3 MB Flash and 1MB SRAM |

| Memory | 1 Gb RAM |

| Storage | 64 Mb QSPI Flash |

| Connectivity | |

| Ethernet | 10BASE-T1L |

| Power Supply | |

| External power | 24 DC @ 6A |

| Power over Ethernet | SPoE class 12 |

| Operating Conditions | |

| Temperature range | -25°C to 60°C |

Applicable Parts

AD74413R

Quad-Channel, Software Configurable Input and Output

MAX14906

Quad-Channel Industrial Digital Output, Digital Input

ADIN1110

Robust, Industrial, Low Power 10BASE-T1L Ethernet MAC-PHY

LTC9111

Industrial SPoE PD Controller

ADP1032

Two-Channel, Isolated Micropower Management Unit with Seven Digital Isolators

MAXQ1065

Ultra Low-Power Cryptographic Controller with ChipDNATM for Embedded Devices

MAX32650

Ultra-Low-Power Arm Cortex-M4 with FPU-Based Microcontroller (MCU) with 3MB Flash and 1MB SRAM

Applications

Industrial Automation Technology (IAT)

- Industrial Sensors and Field Instrument Solutions

- Field Instrument Systems

- Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS)

- Universal Input/Output Module Solutions

Intelligent Building Solutions

- Building Automation Controllers and Network Solutions

- Smart Building Automation Systems

Related Resources

Video

. Nov 20 2024

Industrial Sustainability - The Time for Action is Now!

Application Note

.Nov 6 2024

AN-7669: Using the MAX14916PMB# with TMCM-0960- MotionPy

Application Note

.Nov 6 2024

AN-074: Using the MAX14914PMB with TMCM-0960-MotionPy

Application Note

.Nov 6 2024

AN-073: Using the MAX22190PMB with TMCM-0960-MotionPy

Video

. Oct 8 2024

リモートI/O

Video

. Jun 8 2024

01:14Remote IO

Product Selection Guide

.Mar 27 2024

Precision DACs Product Selection Guide

Video

. Sep 8 2022

Sensors Converge 2022、インテリジェント・エッジの強化

Video

. Aug 8 2022

産業用ネットワーク接続:デジタル・トランスフォーメーションへの課題を解決する鍵

Video

. Jul 28 2022

14:08Sensors Converge 2022, Empowering the Intelligent Edge

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{toggleButtonDescription}}

{{newProjectTitle}}

{{projectNameErrorText}}